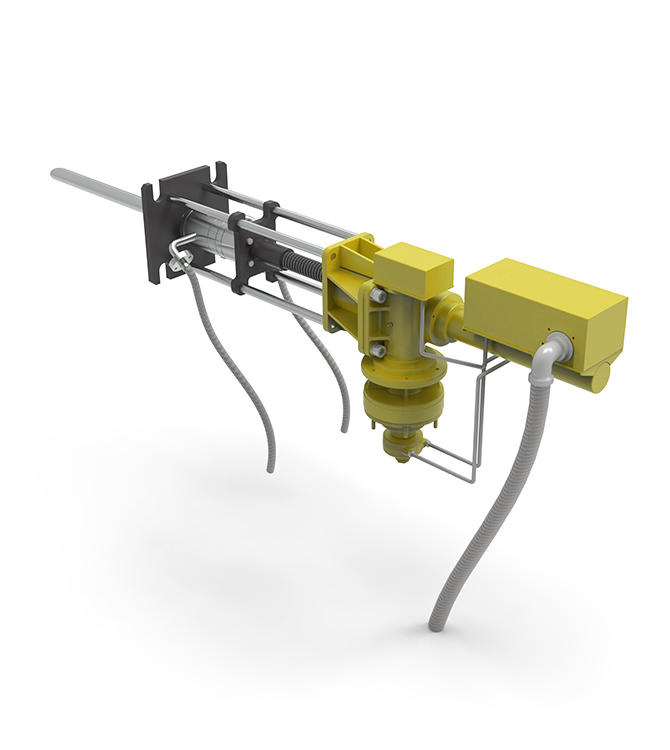

A device that precisely puts injector nozzles into the steel or non-ferrous metal smelting furnaces to feed minerals, fuels, oxygen gas, oxygen-enriched air, etc. for melting minerals.

| Model | KAP-5-300 | KAP-10-300 | KAP-5-350 |

|---|---|---|---|

| Push Weight | 5TON | 10TON | 10TON |

| Stroke | 300mm | 300mm | 350mm |

| Motor RPM | 3000RPM | ||

| Gear Ratio | 1/2088 | ||

| Advence Speed | 0.0525mm/5.25sec(1 motion) | ||

| P.L.C Control Power | AC110V, AC220V | ||

| Pneumatic Supply | 6Kgf/㎠ | ||

| Control Methode | P.L.C & TOUCH SCREEN | ||

The device precisely puts injector nozzles into the steel or non-ferrous metal smelting furnaces to feed minerals, fuels, oxygen gas, oxygen-enriched air, etc. for melting minerals, and can sense and automatically adjust the incoming speed of the injector nozzle and the internal state of the smelting furnace by applying position transmitter.

| Model | KAP-5-300 | KAP-10-300 | KAP-5-350 |

|---|---|---|---|

| Push Weight | 5TON | 10TON | 10TON |

| Stroke | 300mm | 300mm | 350mm |

| Motor RPM | 3000RPM | ||

| Gear Ratio | 1/2088 | ||

| Advence Speed | 0.0525mm/5.25sec(1 motion) | ||

| P.L.C Control Power | AC110V, AC220V | ||

| Pneumatic Supply | 6Kgf/㎠ | ||

| Control Methode | P.L.C & TOUCH SCREEN | ||

The equipment effectively removes various dusts and flue dusts generated on the inner wall of boiler to improve its efficiency. Hitting the wall, its hammer and the driving part are mechanically separated from each other, thereby realizing long life time of the facility and extended life of the equipment.

| Model | KCR-150 | ||

|---|---|---|---|

| Type | FREE FALLING HAMMER | ||

| Cylinder Stroke | 150mm | ||

| Impulse | 23.2kg.m / sec | ||

| Cycle Time | PRESET BY TIMER | ||

| Driving Methode | PNEUMATIC CYLINDER | ||

| P.L.C Control Power | AC110V, AC220V | ||

| Pneumatic Supply | 6Kgf/㎠ | ||

| Control Methode | P.L.C | ||

The equipment is locally installed on the required position to strike it and remove the dust, mist, soot, particulate, etc. that are clogged on the inner wall of the facility.

| Model | HRK-80C | HRK-100C |

|---|---|---|

| Impulse | 15 ~ 23kg.m / sec | 28 ~ 45kg.m / sec |

| Cycle Time | 0-60 / min | 0-60 / min |

| Pneumatic Supply | 3 ~7Kgf/㎠ | |

| Control Methode | P.L.C & PNEUMATIC LOGIC | |

The device that effectively removes various dusts, flue dusts, etc. generated on the inner bundle of a boiler to improve the efficiency of the boiler. It uses the vibration and impact generated from the collision between the bundles to removes foreign materials formed on the bundles.

| Model | KRD-180 |

|---|---|

| Type | PNEUMATIC CYLINDER |

| RAPPING CYLINDER | Ø180 ±100st |

| BLOW | 90 BPM |

| Driving Methode | PNEUMATIC CYLINDER |

| Pneumatic Supply | 6Kgf/㎠ |

| Control Methode | FULL PNEUMATIC LOGIC |

It can adjust top-to-bottom and left-to-right distances with hole tapping and hole blocking systems for discharging furnace metal.

| Model | KMT-2000 |

|---|---|

| Forward stroke | 650mm |

| Drill bit | Ø14 / 610mm |

| Mud cartridge | 1250cc |

| Driving Methode | PNEUMATIC CYLINDER |

| P.L.C Control Power | AC220V, AC110V |

| Pneumatic Supply | 6Kgf/㎠ |

| Control Methode | P.L.C |

The equipment that suppresses the slag solidification phenomenon generated in the furnace slag channel and applies various types of chesels according to the state of the slags to remove them quickly.

| Model | KAC-B-00 | KAC-S-00 |

|---|---|---|

| TYPE | BREAKER | SCRAPER |

| STROKE | ADJUSTABLE | |

| ADVANCE DRIVE TYPE | GEARED MOTOR & RACK AND PINION GEAR | |

| APPROACH TYPE | HYDRAULIC CYLINDER & LM GUIDE | |

| OPERATION | AUTOMATIC & SEMI REMOTE CONTROL | |

| MAIN POWER | AC440V, AC380V | |

| P.C.L CONTROL POWER | AC220V, AC110V | |

| Pneumatic Supply | 6Kgf/㎠ | |

| Control Methode | P.L.C & TOUCH SCREEN | |

Copyright © KUKDO All rights reserved.